Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

Customers can peruse through our list of the various testing and inspection used in our PCB assembly processes.

Printed circuit board assembly is a complex process, and there are possibilities of defects occurring in the process. Faults in PCB assembly can include failures in SMT equipment to incorrect component placement.

Therefore, rigorous testing and inspection is crucial to ensure only the finest quality PCB products are delivered to the client.

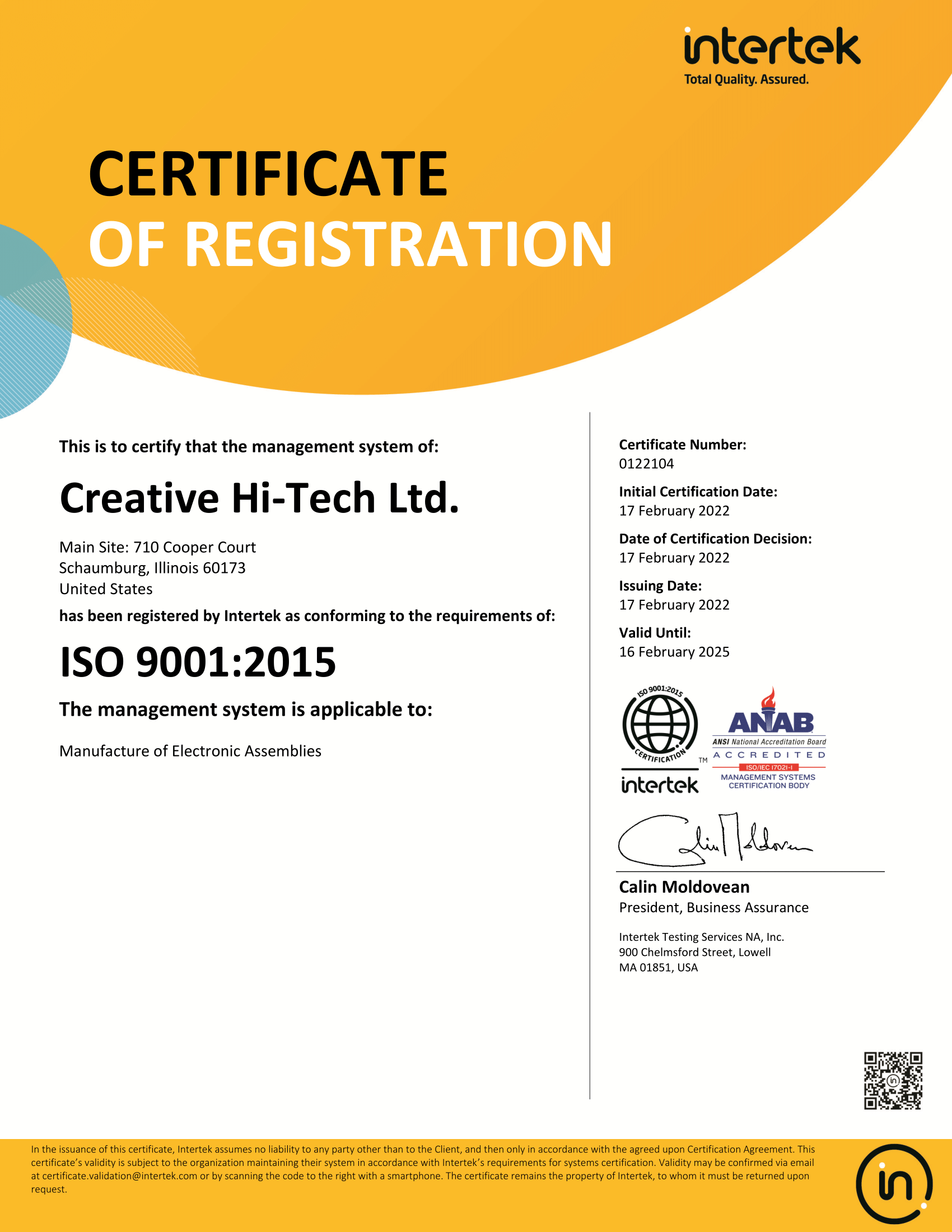

At Creative Hi-Tech Ltd. (CHTL), we employ multiple testing and inspection procedures to ensure best quality PCB assemblies are produced and delivered to the customer. We emphasize on effective quality control to avoid rework. This allows us to lower overall product costs and ensure efficient resource management.

Extensive testing and inspection procedures are implemented throughout the PCB assembly process to detect faults early on, ensuring high product quality and yield.

Our extensive testing capabilities are suited for the most demanding PCB assembly requirements. We create apposite testing strategies according to the product design, component selection, and batch volume. Following are highlights of CHTL’s comprehensive testing capabilities:

At CHTL, we use the most advanced testing and inspection equipment for PCB assembly consisting of:

We can meet every requirement associated with PCB assembly and production processes with our comprehensive testing and inspection capabilities. If you have any queries about our PCB assembly and testing processes, feel free to contact us. You can call us at 224.653.4000, or send an email at sales@creativehitech.com. We will get back to you within one business

Looking for an instant quote for your next PCB assembly project? Use our advanced online PCB calculator to receive competitive pricing tailored to your specific requirements.

Selecting the right materials is crucial for the performance and longevity of your printed circuit boards (PCBs). At Creative Hi-Tech, we offer:

Diverse Material Selection: From FR-4 and FR-5 to CEM-1, CEM-3, copper, Rogers (RF), high Tg materials, and aluminum, we provide a wide range of options to meet specific application requirements.

Customization and Flexibility: Our team collaborates closely with clients to understand their unique needs, offering tailored solutions from initial design to full-scale production.

Quality Assurance: We adhere to IPC and RoHS standards, ensuring that all materials and processes meet stringent quality and environmental guidelines.

Advanced Capabilities: Equipped with state-of-the-art facilities and a knowledgeable team, we handle complex projects across various industries, delivering reliable and high-performance PCB assemblies.

Partner with Creative Hi-Tech for comprehensive PCB material solutions that align with your project's technical and regulatory requirements.