Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

Small volume PCB assembly, also known as low volume PCB assembly, refers to an assembly of PCBs in the range of 25-5000 with Design for Manufacturability (DFM), and Design for Testability (DFT).

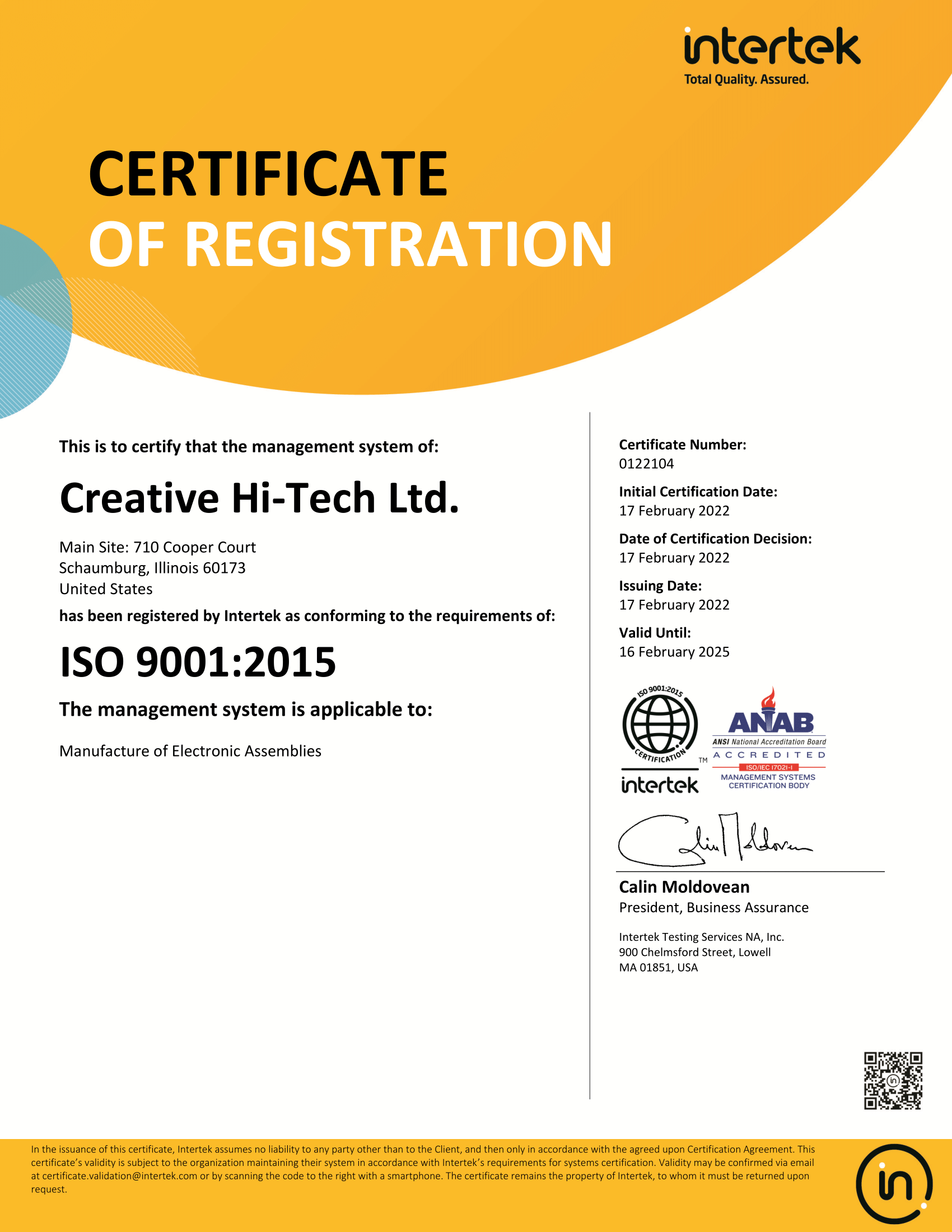

Creative Hi-Tech is an electronic contract manufacturer (ECM) providing turnkey services in small volume printed circuit board (PCB) assembly including parts procurement, PCB fabrication, as well as final assembly.

At Creative Hi-Tech, we provide the following types of assemblies:

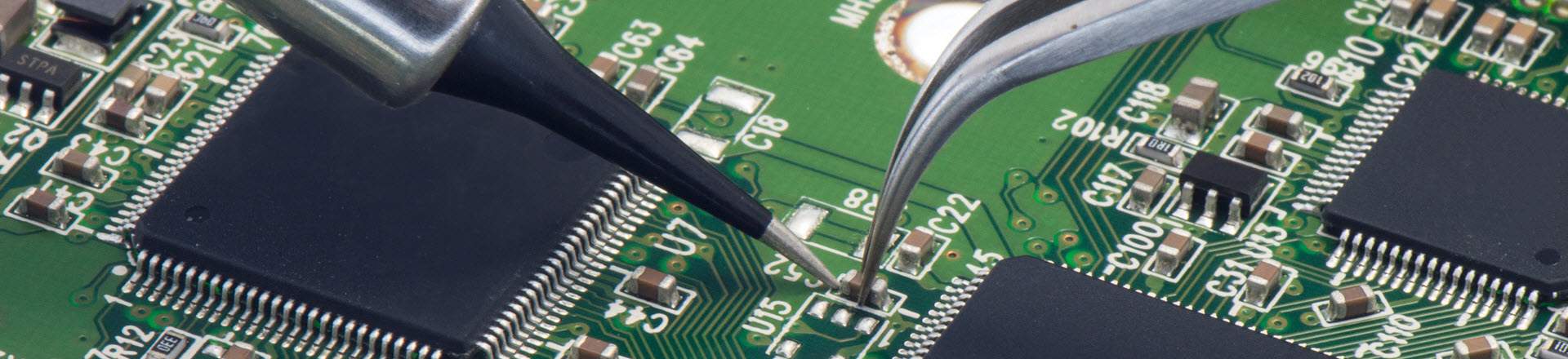

We currently provide placement of repair and placement of components on a 7mil pitch, BGA, μ-BGA, QFN, ultra-fine pitch QFP, CSP, FCP, and 0201 boards. Also, we provide PCB testing and inspection services such as optical inspection, and X-ray laminography, which allows us to inspect all solder joints meticulously.

Design for Manufacturing Services (DFM): We employ Design for Manufacturing Services (DFM) to avoid delays in the engineering process, and speed up our delivery. We conduct a detailed review of our clients’ documents such as BOMs, circuit diagrams, Gerber files, and assembly drawings. Additionally, we conduct a review of the clients’ parts list to ensure its accuracy before ordering the parts. Also, we suggest a solder mask for improving yield rates. This service helps us reduce errors, and keep production costs to a minimum. This in turn allows our clients to avail our services at low prices.

Design for Testing Services (DFT):Through this service, we recommend our clients on placing test points in their PCB. This support service helps our PCB clients decide on fixtures, probe types, and understand the limitations of testing procedures. The DFT service tests also identify the functionality of testing requirements, diagnostic instructions, problem identification, and other references.

Pre-production Samples of PCBs: We can produce small PCB quantities, and send them for the client’s review before proceeding to large scale manufacturing. This helps us avoid production risks, errors, and added expenses related to rework. Once the order is finalized by the client, we inspect and test all manufactured PCBS, and the quality of lead-free part assembly via advanced X-ray inspection equipment. We don’t ship PCBs until they pass rigorous quality standards set by us, or until all errors are rectified.

Design Changes:Prototypes are tangible products, which help customers understand how their PCBs are going to look during the final stage. These prototypes allow clients to decide whether they want to proceed with the large production of PCBs.

Rigorous Testing and Troubleshooting: All prototypes undergo rigorous testing before leaving our premises. This assures clients that the PCBs will work as expected.

Quality Assurance: We use advanced testing equipment to ensure the components are working as per the client’s requirements. Also, we check if certain components need repair, or need to be replaced.

Competitive Prices: We conduct our services in our state-of-the art facility. Our tested and proven procedures help reduce errors, speed up time to market, and minimize waste.

We provide a turnkey service in which our experts will purchase the components and circuit boards for assembly. However, most often our clients provide us raw boards and components and we complete the assembly. To know more about low volume PCB assembly services, contact us today via phone at 224.653.4000, or email your Gerber files and BOM lists to sales@creativehitech.com.

Looking for an instant quote for your next PCB assembly project? Use our advanced online PCB calculator to receive competitive pricing tailored to your specific requirements.

Selecting the right materials is crucial for the performance and longevity of your printed circuit boards (PCBs). At Creative Hi-Tech, we offer:

Diverse Material Selection: From FR-4 and FR-5 to CEM-1, CEM-3, copper, Rogers (RF), high Tg materials, and aluminum, we provide a wide range of options to meet specific application requirements.

Customization and Flexibility: Our team collaborates closely with clients to understand their unique needs, offering tailored solutions from initial design to full-scale production.

Quality Assurance: We adhere to IPC and RoHS standards, ensuring that all materials and processes meet stringent quality and environmental guidelines.

Advanced Capabilities: Equipped with state-of-the-art facilities and a knowledgeable team, we handle complex projects across various industries, delivering reliable and high-performance PCB assemblies.

Partner with Creative Hi-Tech for comprehensive PCB material solutions that align with your project's technical and regulatory requirements.