Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

As a part of our technical capabilities, we also provide a list of materials and the specifications of the PCB, as well as its components and assembly.

As part of our technical capabilities, we provide detailed material lists and specifications for every PCB assembly, ensuring that all components meet the highest industry standards. Our expertise extends beyond simply assembling PCBs—we collaborate with clients to optimize designs, select the best materials, and fine-tune specifications for enhanced performance and durability.

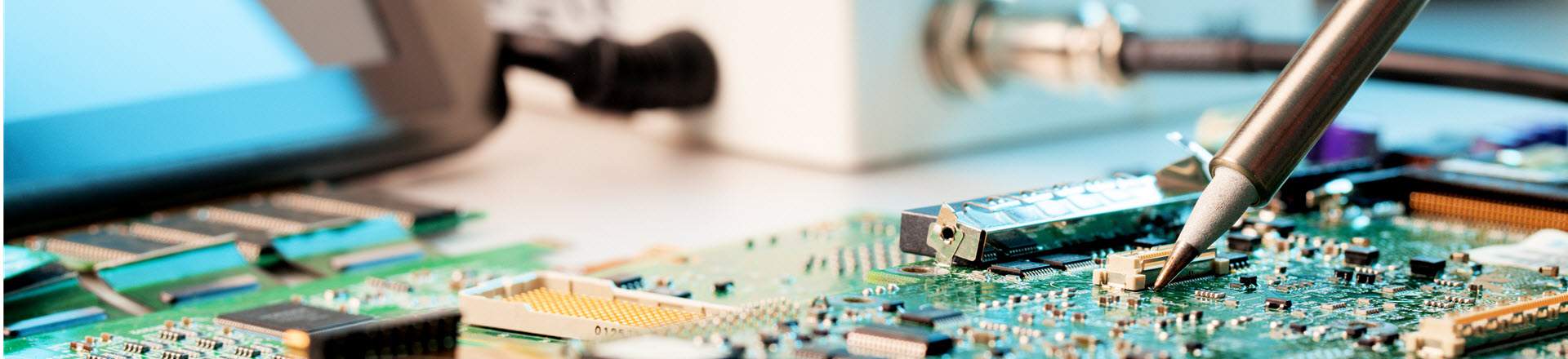

Over the years, Creative Hi-Tech Ltd. (CHTL) has earned the trust of numerous industries by consistently delivering high-quality, custom PCB assemblies. Our ability to take on projects of any complexity sets us apart, whether it's:

A new concept requiring design and assembly support.

A schematic with Gerber file specifications for precise PCB fabrication.

A complete end-to-end PCB production process, from design to delivery.

We achieve this level of excellence through our deep industry knowledge, cutting-edge manufacturing equipment, and commitment to quality. By leveraging state-of-the-art resources and a highly skilled team, we ensure that every PCB meets the unique demands of its intended application, from aerospace and telecommunications to medical and industrial electronics.

At Creative Hi-Tech, we go beyond standard PCB manufacturing—we provide full-scale PCB material selection, design optimization, and advanced assembly solutions to help our clients succeed in their industries.

One resource that we focus on immensely is manufacturing materials. We spare no expense to utilize industrial grade materials for every assignment. The use of high quality materials supports the performance and longevity of our printed circuit boards in eclectic industrial applications. Given below is a list of the primary materials that we work with regularly.

FR-4: An extremely popular PCB material, this is a glass-reinforced epoxy laminate, constructed using woven fiberglass, and a flame retardant resin binder. The binder is the reason for the name ‘FR’. As a material, FR-4 is an excellent electrical insulator, and possesses immense mechanical strength. It is also known for its slow moisture absorption capabilities, and good fabrication characteristics.

FR-5: This is a thermosetting fiberglass composite. It comprises continuous filament glass material, and an epoxy resin binder. FR-5 is known for its chemical resistance, low moisture absorption capabilities, immense strength, and excellent electrical properties.

CEM-1: This material is a part of the group Composite Epoxy Materials (CEM). The group consists of non-woven glass cores, epoxy synthetic resins, and woven glass fabric. This type is chosen as it is inexpensive, and flame retardant.

CEM-3: Another type of composite epoxy material, CEM-3 is flame retardant, and is very similar to FR-4.

Copper: Generally, copper is chosen as the primary material to create single and multiple layers in a PCB. As a metal, copper provides benefits of high strength levels, low chemical reactivity, and high thermal and electrical conductivity.

Rogers: Also known as RF, Rogers is best known for its compatibility with FR-4 laminates. It provides benefits of high thermal conductivity, controlled impedance, and allows for easy lead-free circuit board processing.

High Tg: High Tg stands for high glass transition temperature. This material is an excellent choice for PCBs that are used in demanding applications. The Tg material is known for its high temperature durability, as well as long delamination durability.

Aluminum: This is another popular material, as aluminum is used to prevent copper circuit pattern layers from overheating. Aluminum is primarily chosen for its immense ability to dissipate heat quickly. It is a ductile and malleable metal, and has excellent corrosion resistance.

Halogen Free Aluminum: This metal is an option when a customer requires eco-friendly PCBs for an application. Halogen free aluminum is known for its improved dielectric constant, as well as moisture diffusivity.

Looking for an instant quote for your next PCB assembly project? Use our advanced online PCB calculator to receive competitive pricing tailored to your specific requirements.

Selecting the right materials is crucial for the performance and longevity of your printed circuit boards (PCBs). At Creative Hi-Tech, we offer:

Diverse Material Selection: From FR-4 and FR-5 to CEM-1, CEM-3, copper, Rogers (RF), high Tg materials, and aluminum, we provide a wide range of options to meet specific application requirements.

Customization and Flexibility: Our team collaborates closely with clients to understand their unique needs, offering tailored solutions from initial design to full-scale production.

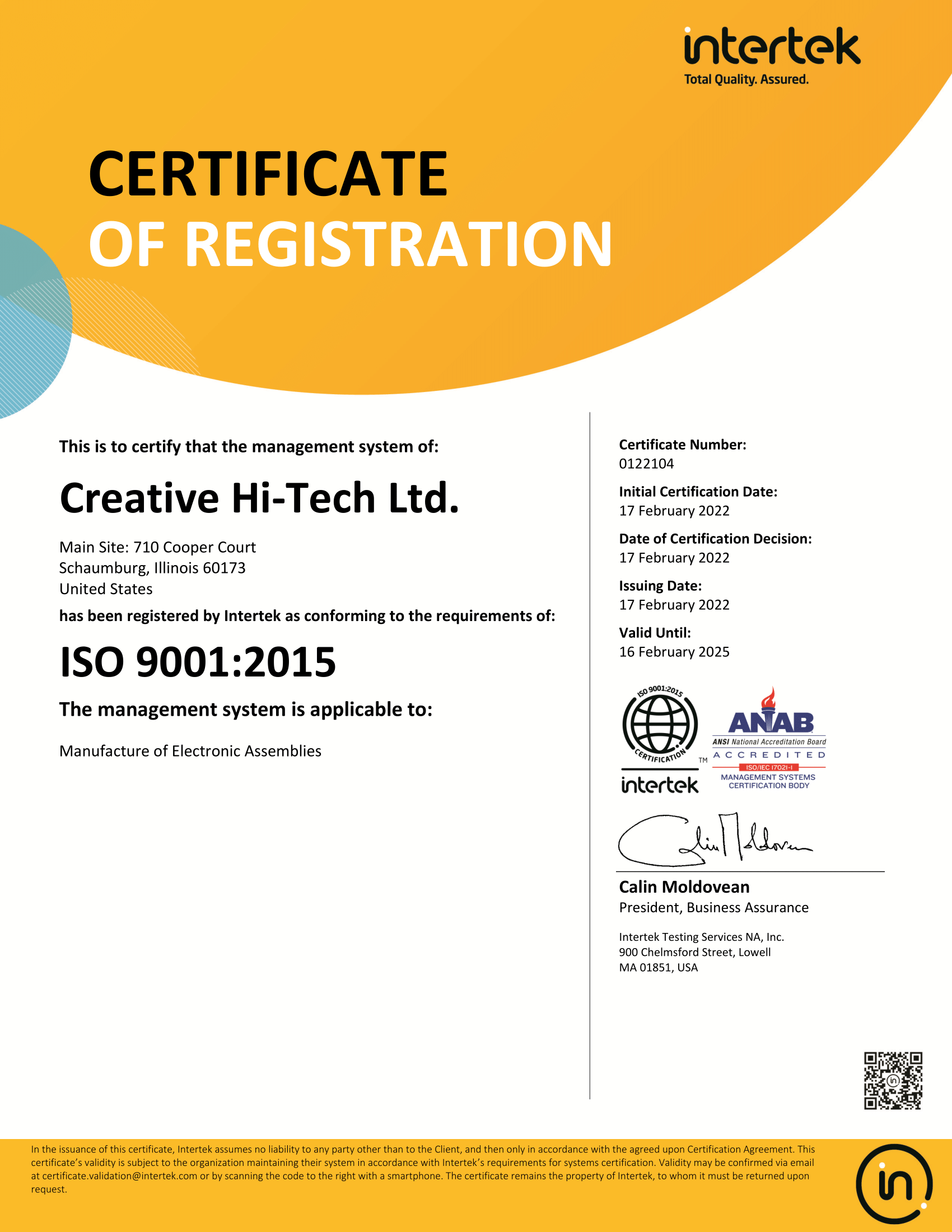

Quality Assurance: We adhere to IPC and RoHS standards, ensuring that all materials and processes meet stringent quality and environmental guidelines.

Advanced Capabilities: Equipped with state-of-the-art facilities and a knowledgeable team, we handle complex projects across various industries, delivering reliable and high-performance PCB assemblies.

Partner with Creative Hi-Tech for comprehensive PCB material solutions that align with your project's technical and regulatory requirements.