Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

The RoHS (Restriction of Hazardous Substances) directive does not allow the usage of six hazardous materials from use in electronic and electrical equipment manufacturing. Lead, which is used in Printed Circuit Board (PCB) manufacturing is one of the materials among the six. With this in mind, Creative Hi-Tech designs and manufactures lead-free PCBs. This means that in our PCBs, we exclude materials such as:

With the directive in action, we focus on implementing lead-free PCB assembly technologies, and processes to manufacture RoHS compliance PCBs. Advanced equipment used in our processes play a vital role in producing the best results. We also provide services in migrating our customers from leaded to lead-free PCB designs. Our capabilities include:

|

Material

|

RoHS-compliant FR-4

|

|

Surface Finishes

|

Lead-free Solder Finish (lead-free HASL) Electroless Nickel Immersion Gold (ENIG) |

|

Services

|

Lead trimming system |

|

Thermal Mass Assembly Reflow

|

Low: 240°C –245°C High: 260°C |

Our lead-free PCB assembly process includes following steps:

Owing to the following benefits, a lead-free PCB is preferred over the leaded one:

With the capabilities mentioned in the table above, it has helped us to serve a wide range of industries varying from Aerospace and Satellite, LED, Medical industries, to wireless, military, and telecommunications industries.

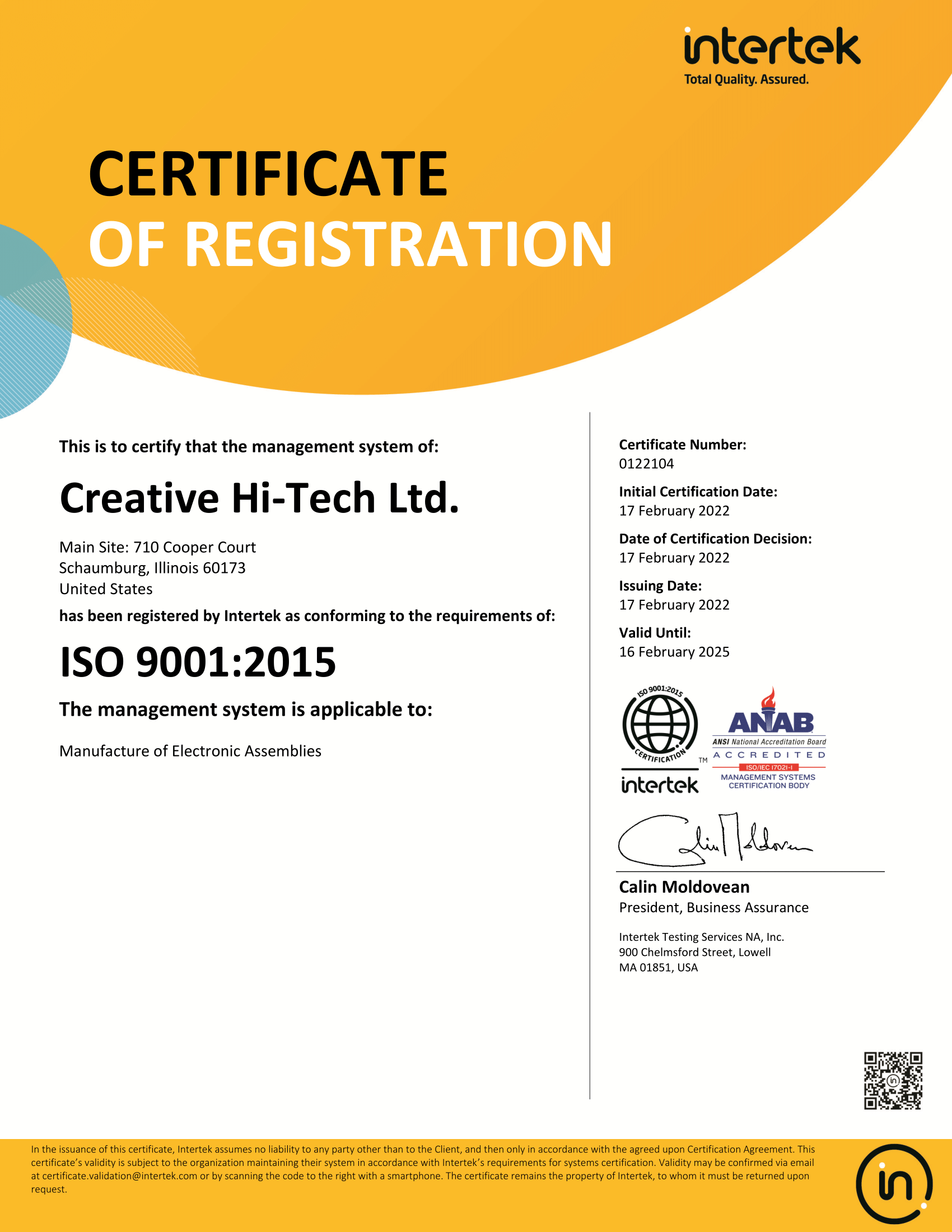

The skilled technicians and engineers work with you to understand your product requirements and deliver a product that best suits your application requirements. We follow all the required industry standards such as:

You can contact us for any queries about lead-free PCB assembly services. Feel free to call us at

, or email at sales@creativehitech.com. We will get back to you within one business day.

Looking for an instant quote for your next PCB assembly project? Use our advanced online PCB calculator to receive competitive pricing tailored to your specific requirements.

Selecting the right materials is crucial for the performance and longevity of your printed circuit boards (PCBs). At Creative Hi-Tech, we offer:

Diverse Material Selection: From FR-4 and FR-5 to CEM-1, CEM-3, copper, Rogers (RF), high Tg materials, and aluminum, we provide a wide range of options to meet specific application requirements.

Customization and Flexibility: Our team collaborates closely with clients to understand their unique needs, offering tailored solutions from initial design to full-scale production.

Quality Assurance: We adhere to IPC and RoHS standards, ensuring that all materials and processes meet stringent quality and environmental guidelines.

Advanced Capabilities: Equipped with state-of-the-art facilities and a knowledgeable team, we handle complex projects across various industries, delivering reliable and high-performance PCB assemblies.

Partner with Creative Hi-Tech for comprehensive PCB material solutions that align with your project's technical and regulatory requirements.