Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

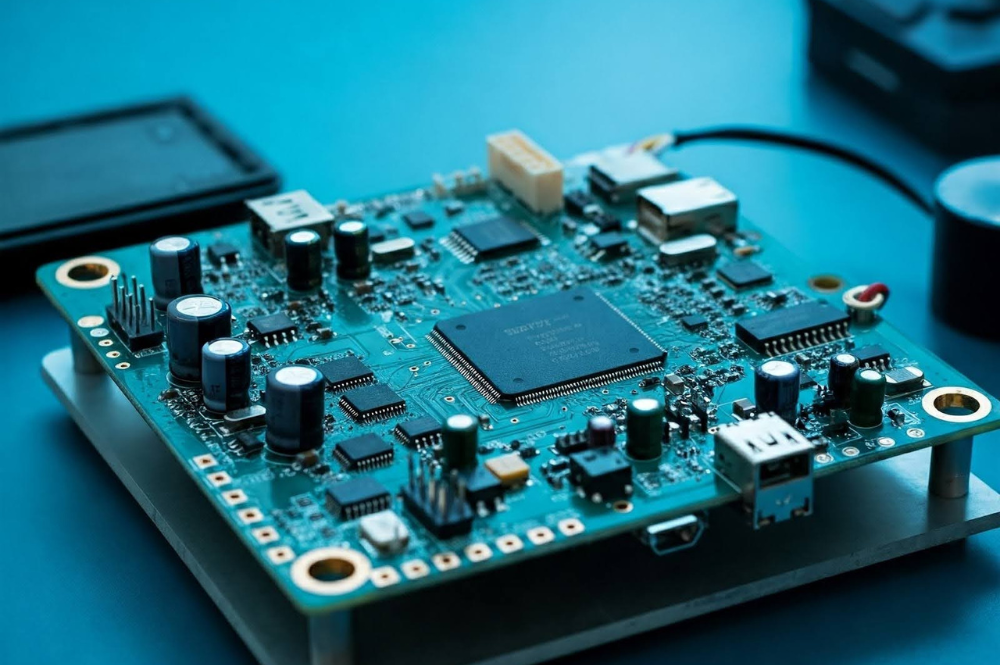

During the initial phases of product development, it is crucial to identify and correct design issues before mass production. Prototype PCB assembly allows engineers to test circuit layouts, assess component compatibility, and ensure functionality under real-world conditions. Key benefits include:

Detecting errors before full-scale production – Avoid costly redesigns by catching flaws early.

Optimizing component placement – Ensure efficient PCB layout for performance and manufacturability.

Verifying electrical performance – Test signal integrity, power distribution, and thermal management.

By addressing these concerns early in the development cycle, manufacturers can save time and resources while improving product reliability.

Beyond functionality, prototype PCB assembly helps fine-tune manufacturing processes to enhance efficiency. Engineers can experiment with different soldering techniques, materials, and assembly methods to determine the best approach for high-volume production. Benefits include:

Reducing production errors – Testing ensures manufacturability and assembly efficiency.

Enhancing quality control – Prototype testing minimizes defects and improves yield rates.

Validating design for regulatory compliance – Ensure adherence to industry standards before mass production.

With a well-tested prototype, manufacturers can confidently scale up production without unexpected setbacks.

Speed is critical in product development, especially in competitive industries like consumer electronics, medical devices, and telecommunications. Quick turn PCB solutions provide an accelerated path from design to prototype testing, offering:

Fast prototyping – Receive fully assembled prototypes in as little as 1-5 days.

Shorter iteration cycles – Rapidly test and refine designs with quick turnaround times.

Faster product launches – Reduce delays and gain a competitive edge in the market.

By leveraging quick turn PCB solutions, companies can quickly evaluate multiple design iterations, ensuring they bring the best possible product to market in the shortest timeframe.

In today’s fast-paced tech landscape, innovation depends on agility and precision. Prototype PCB assembly bridges the gap between concept and production, enabling engineers to explore new ideas without the risk of costly errors. When combined with quick turn PCB solutions, businesses can:

Minimize risks in product development

Streamline design improvements

Meet tight deadlines without sacrificing quality

At Creative Hi-Tech, we specialize in prototype PCB assembly and quick turn PCB solutions to help businesses accelerate their product development cycles. Our advanced capabilities ensure high-quality prototypes with fast turnaround times, allowing you to refine your designs and bring your innovations to market faster.

Contact us today at 224-653-4000 or email sales@creativehitech.com to discuss your PCB prototyping needs and see how we can support your next project.

Prototype PCB assembly is the process of creating and testing small-batch circuit boards before full-scale production to identify design flaws and improve functionality.

Quick turn PCB solutions accelerate the prototyping process, allowing businesses to test and refine designs quickly, reducing time-to-market.

Industries such as consumer electronics, medical devices, automotive, aerospace, and telecommunications rely on prototype PCB assembly to develop reliable and innovative products.

Quick turn PCB assembly can take as little as 1-5 days, depending on complexity and order volume.

Testing ensures that the PCB functions correctly, meets industry standards, and can be efficiently manufactured at scale, reducing production risks.