Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

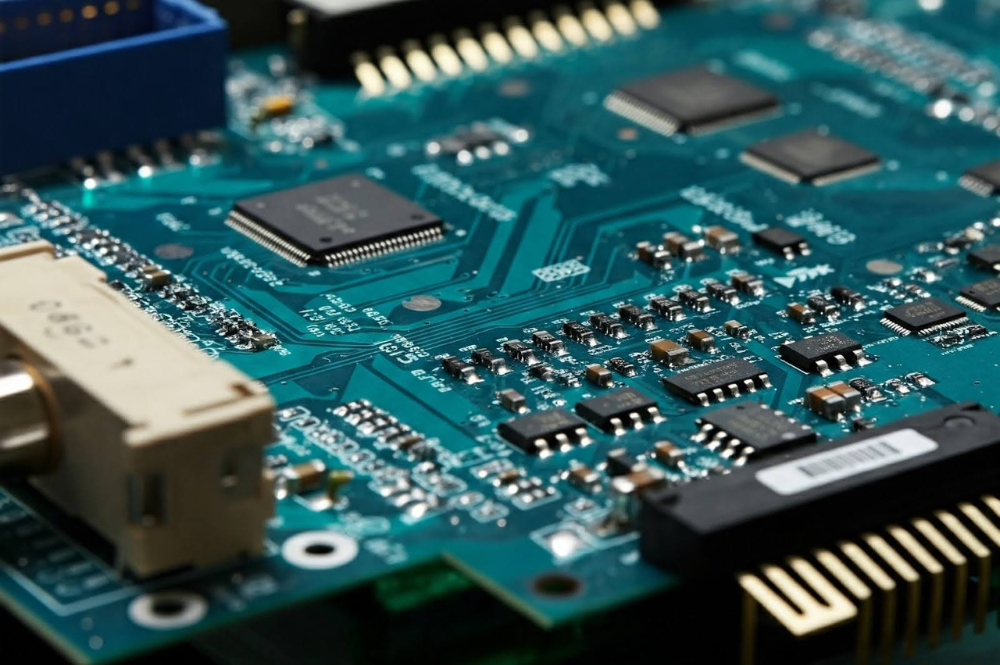

In the healthcare industry, advanced PCB technology has transformed the way medical professionals diagnose, monitor, and treat patients. High-density, multi-layer PCBs enable the development of compact yet powerful devices such as:

Wearable health monitors – Heart rate trackers, glucose monitors, and fitness wearables rely on miniaturized PCBs for real-time health tracking.

Imaging and diagnostic equipment – CT scanners, MRI machines, and X-ray devices require precision PCBs to process high-resolution imaging data.

Implantable medical devices – Pacemakers and neurostimulators use ultra-reliable PCBs that meet strict safety and performance standards.

As PCB fabrication services advance, the medical industry benefits from smaller, more efficient, and longer-lasting electronic components that improve patient care.

The aerospace sector depends on advanced PCB technology for mission-critical applications that require exceptional durability and performance. PCBs used in aerospace applications must withstand extreme temperatures, vibrations, and radiation exposure. Key applications include:

To meet these stringent requirements, PCB fabrication services incorporate high-grade materials such as ceramic substrates, flexible laminates, and thermal-resistant composites, ensuring long-lasting performance in aerospace environments.

As the demand for faster, more reliable internet and communication networks grows, advanced PCB technology plays a crucial role in supporting telecommunications infrastructure. Key innovations include:

With ongoing advancements in PCB fabrication services, the telecommunications sector can continue to innovate, providing seamless connectivity for businesses and consumers alike.

As technology evolves, PCB fabrication services must adapt to meet the demands of emerging applications. Several key advancements are shaping the future of PCB manufacturing:

New materials for enhanced performance – The use of high-frequency laminates, flexible substrates, and conductive inks is improving PCB efficiency and durability.

Precision manufacturing techniques – Laser drilling, advanced soldering processes, and automated inspection systems are increasing accuracy and consistency in PCB production.

Integration with IoT devices – The rise of the Internet of Things (IoT) is driving demand for compact, high-performance PCBs that enable seamless connectivity in smart devices.

These innovations allow advanced PCB technology to support more complex and efficient electronic systems across industries, paving the way for further technological breakthroughs.

At Creative Hi-Tech, we provide industry-leading PCB fabrication services to help businesses innovate and stay ahead of technological advancements. Whether you need precision PCBs for healthcare, aerospace, or telecommunications, our expertise in advanced PCB technology ensures high-quality, reliable solutions.

Contact us today at 224-653-4000 or email sales@creativehitech.com to discuss your PCB fabrication needs and discover how we can support your next project.

PCB fabrication services involve designing, manufacturing, and assembling printed circuit boards used in electronic devices. These services ensure PCBs meet performance, durability, and compliance standards for various industries.

Advanced PCB technology enhances performance, reduces size, and improves power efficiency in electronic devices. It enables better heat management, faster data processing, and greater reliability in complex applications.

Industries such as healthcare, aerospace, telecommunications, automotive, and consumer electronics rely on PCB fabrication services for high-performance, mission-critical applications.

IoT devices require compact, high-speed PCBs to enable wireless connectivity, data processing, and integration with smart networks. Advanced PCB designs help optimize power consumption and communication efficiency.

High-performance PCBs use materials such as ceramic substrates, flexible laminates, and high-frequency laminates to enhance durability, heat resistance, and signal integrity.